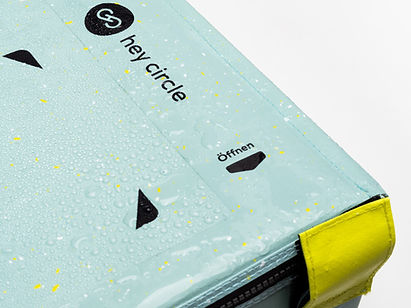

For a more sustainable ecommerce experience

The ecommerce has a waste problem. The German ecommerce alone is responsible for 1.5 Mio. tons of waste (50 kg per second) and 3 Mio. tons CO₂ -Emissionen through use of disposable shipping packaging. Choose "reuse" instead!

Ökobilanz

By using the hey circle boxes and bags, waste and CO₂ are avoided.

The waste avoidance is obvious. But what about CO₂?

We asked the renowned Ökopol Institute to do the lifecycle assessment.

The result: The box saves CO₂ after 10 cycles compared to the disposable carton*.

We use recyclable material

The hey circle packaging is made of recyclable materials. It's polypropylene (PP), with less than 3% polyester (yarn, zipper fabric, velcro). Both plastics are recyclable and have established recycling streams in Germany.

Since 2025 we are using recycled material (rPP). As material shares differ in every product, please ask us regarding the repective hey circle product that you are using.

Over a lifetime of 50 circulations hey circle saves 94 % waste and 76 % CO2 emissions.

We are often asked whether the CO₂ balance of our box is negative due to the need to return empty packaging. The Ökopol environmental assessment shows: Most of the emissions occur during the production of each newly produced disposable box. Returning and cleaning reusable shipping packaging generates CO₂ emissions, too. But, making disposable boxes emits more CO₂ over their lifespan. We plan on renewing our ecological evaluation in 2025 - as our products become even more long living and sustainable.

Disposable cartons (80% recyclate) were compared with the hey circle size L (0% recyclate) over a service life of 50 cycles. Ecological evaluation by Ökopol (APR 2023)

Sustainability is work in progress

Our mission is to avoid waste and CO₂ and to constantly expand our impact. In doing so, we try to get a little better every day. Because: we are not perfect. On some issues, we have to start with compromises and evolve towards our goals. We pay attention to transparency and discuss in each point where a compromise is justifiable and where not.

We are working on the following sustainable development goals